Yeah, I have to always remember to "warm up" on a scrap piece - before getting near anything valuable.RuZty wrote:Whenever I weld something that matters or if someone else has used the welder I always check the settings on a test piece first.

RZ350 Super Motard

Moderator: rztom

Re: RZ350 Super Motard

Re: RZ350 Super Motard

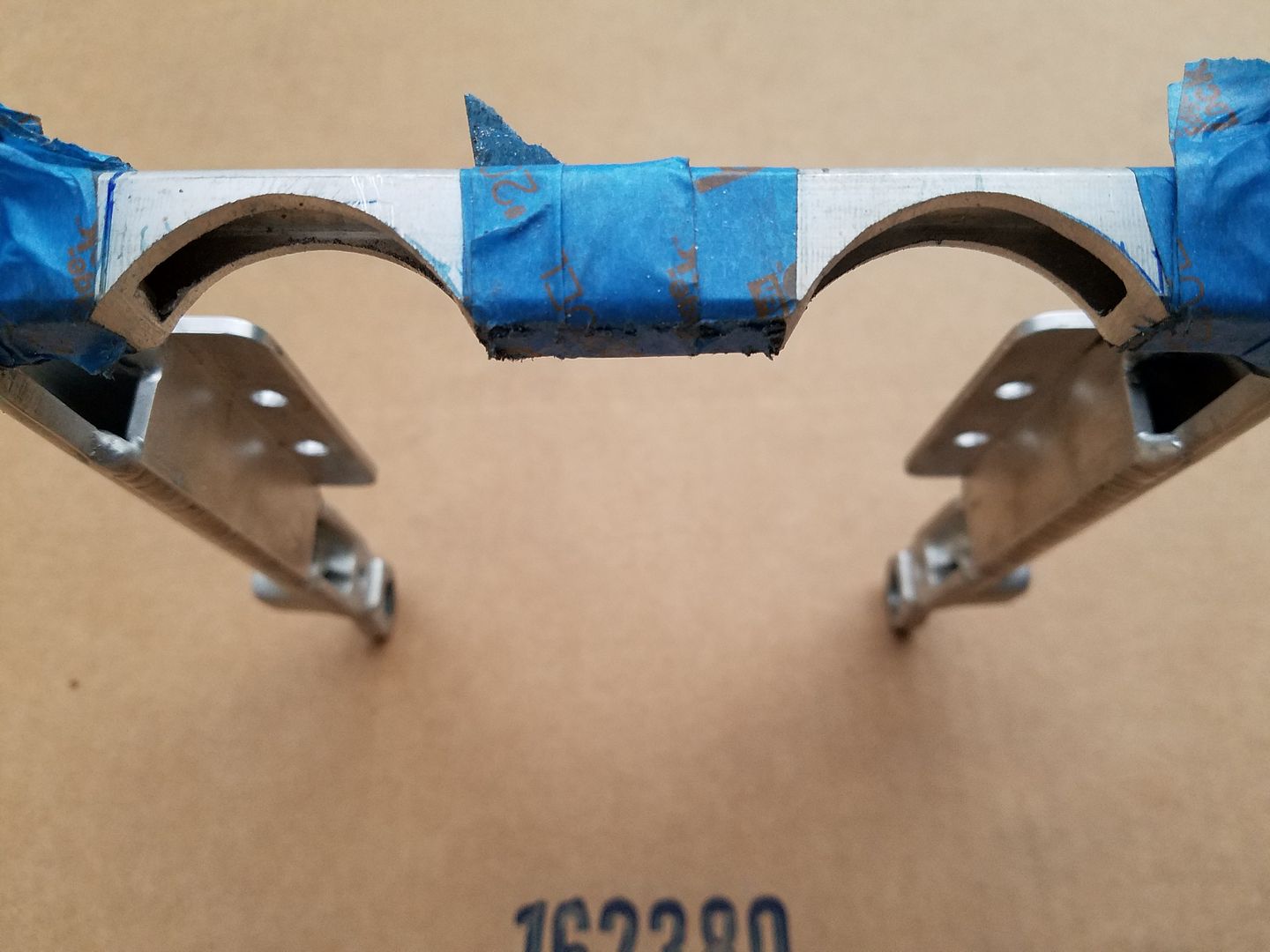

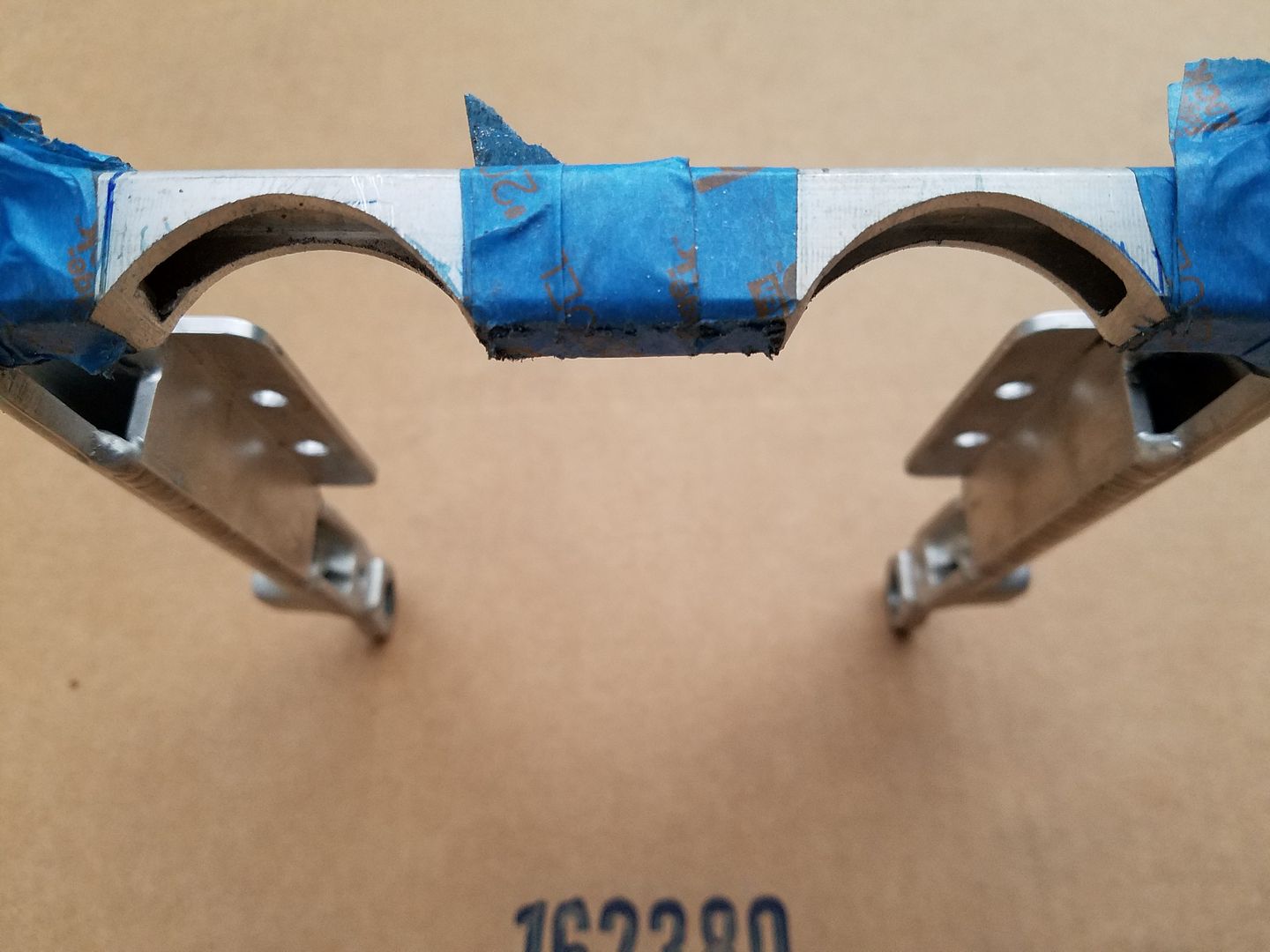

Progress on the silencer brackets. Welded, drilled and tapped for M8 bolts.

The shape and angle will match the factory brackets.

Next is drilling and tapping for helicoils which will be inserted in the aluminum silencers.

The shape and angle will match the factory brackets.

Next is drilling and tapping for helicoils which will be inserted in the aluminum silencers.

Re: RZ350 Super Motard

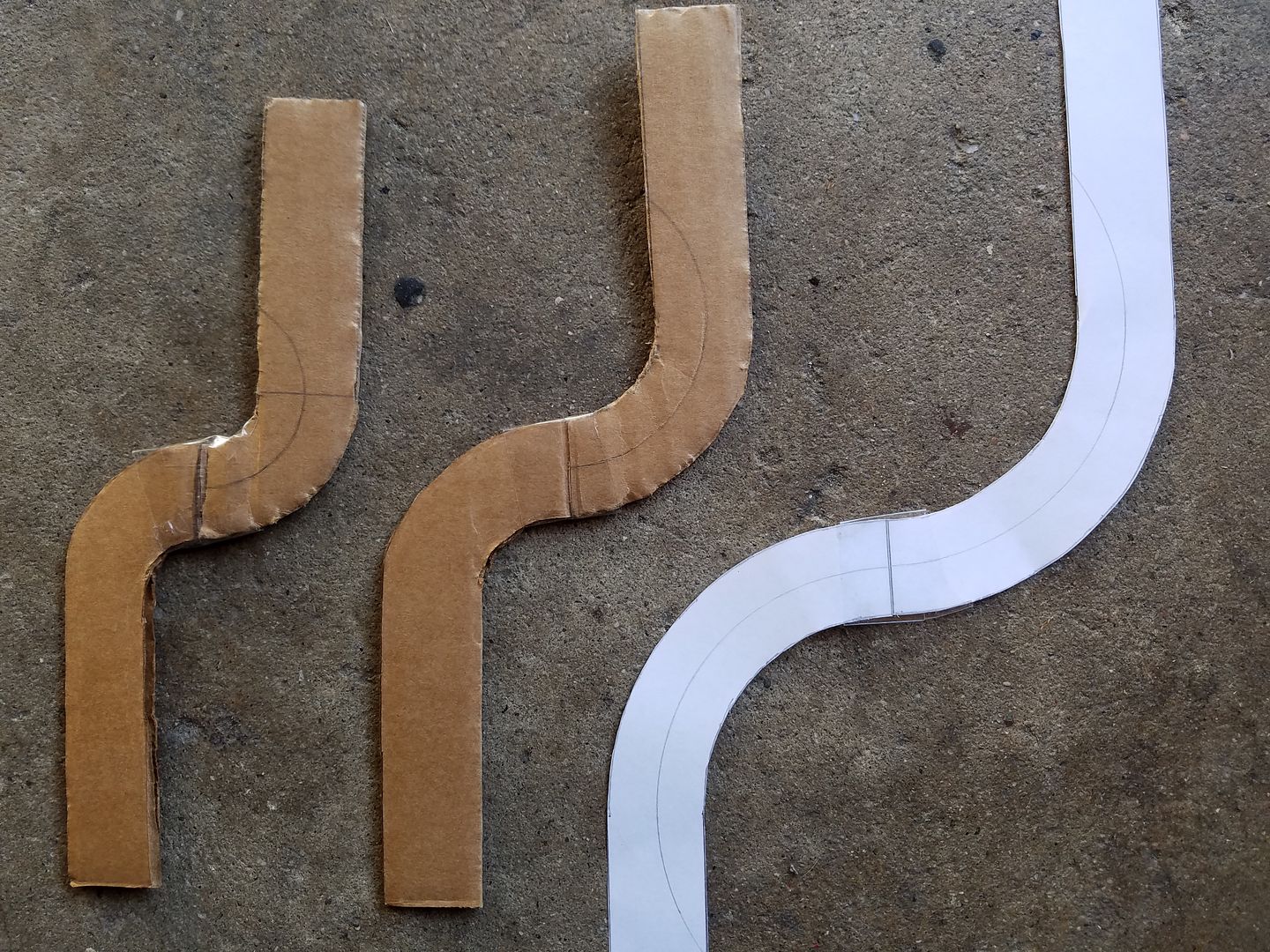

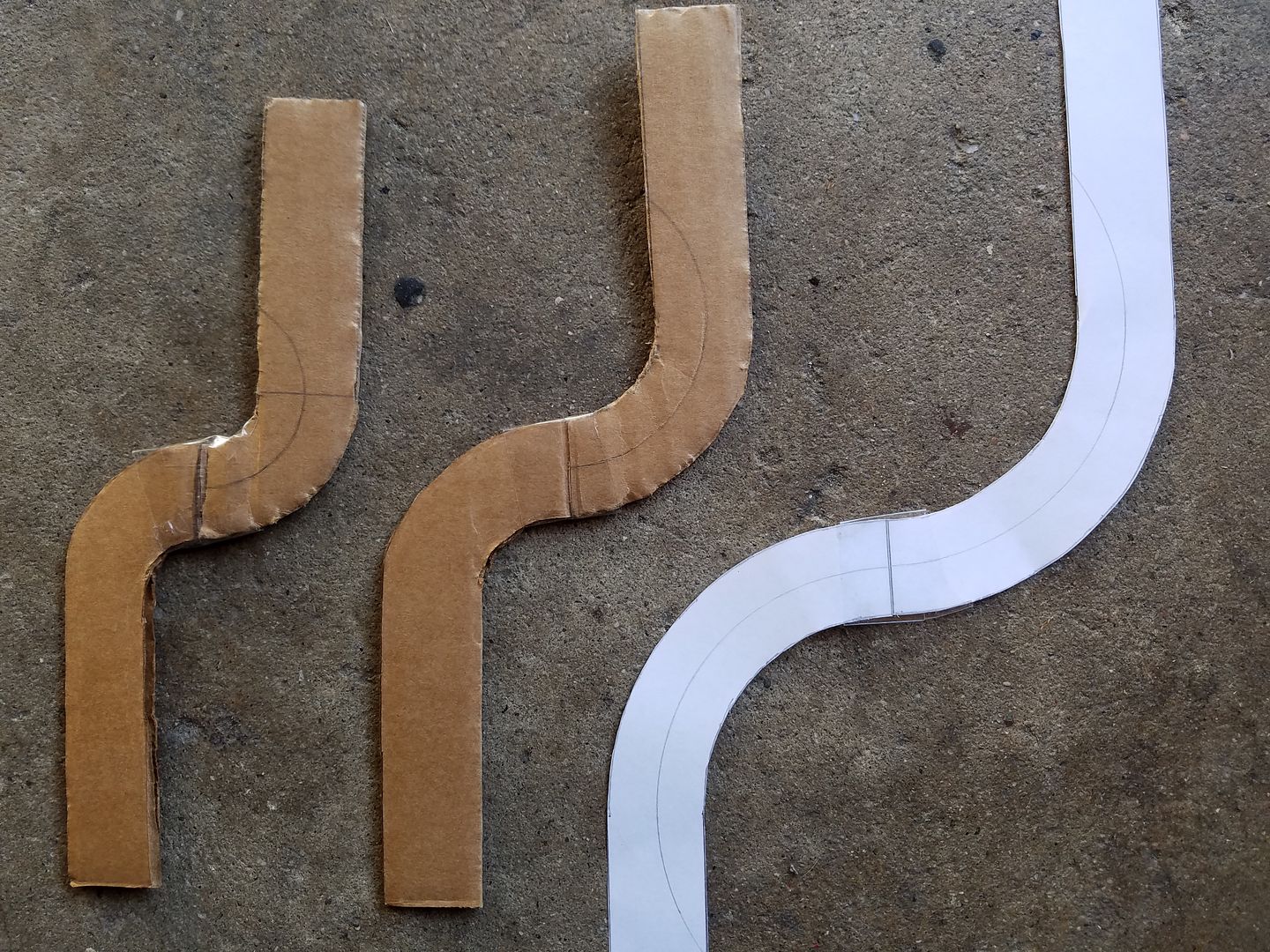

Before welding the bracket for the silencers, I need to make sure I can fit the in- and out-tubing.

I could try to find a company to make these tight bends, but I'd like to do it myself.

Found some stainless tubing available online and made templates to try on the bike for the in-tubing. Takes the tightest bend I could find. 16 gauge with 1 inch O.D. and 1 inch CLR. Buying 2 U-bends to slice in half, turn one leg around to create an S-bend and weld together with a stainless ring over the cut. Hope that makes sense. Anyway, I can determine the clearance on one side.

I could try to find a company to make these tight bends, but I'd like to do it myself.

Found some stainless tubing available online and made templates to try on the bike for the in-tubing. Takes the tightest bend I could find. 16 gauge with 1 inch O.D. and 1 inch CLR. Buying 2 U-bends to slice in half, turn one leg around to create an S-bend and weld together with a stainless ring over the cut. Hope that makes sense. Anyway, I can determine the clearance on one side.

Last edited by Smoker on Sat Nov 04, 2017 7:22 pm, edited 1 time in total.

- two-stroke-brit

- -----

- Posts: 1701

- Joined: Fri Nov 22, 2013 10:49 pm

- Location: Houston texas

Re: RZ350 Super Motard

i repaired a kendon trailer and needed some 1.25"x.1 wall thicknesss steel pipe bent ,

found a local company that did 4 pieces for $75 .

just FYI .

cheers mark

found a local company that did 4 pieces for $75 .

just FYI .

cheers mark

350LC,Athena 392 big bore,stock porting,swiss cheese air box,stock reeds,spec11 pipes.(now TSA big bore pipes)

She might not be pretty but she will always be a fun ride

1982 YAMA RD350LC

98KDX 220R

1967 TRIUMPH TIGER

2001 TRIUMPH TT600

She might not be pretty but she will always be a fun ride

1982 YAMA RD350LC

98KDX 220R

1967 TRIUMPH TIGER

2001 TRIUMPH TT600

Re: RZ350 Super Motard

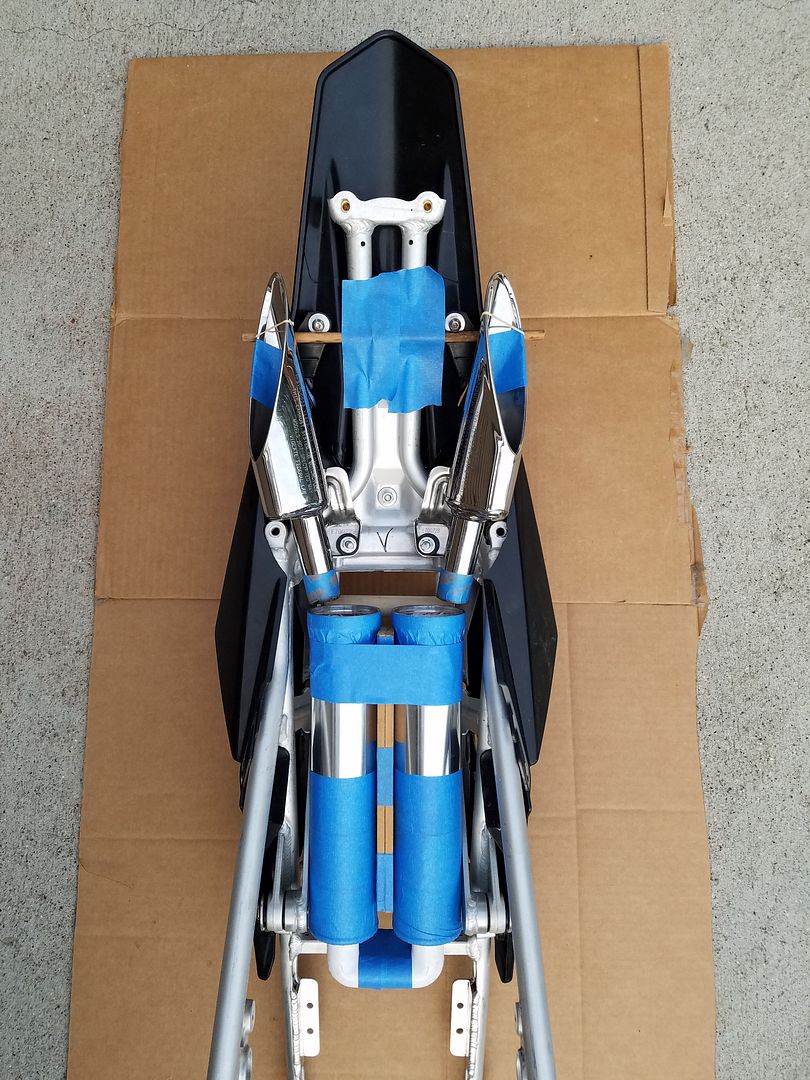

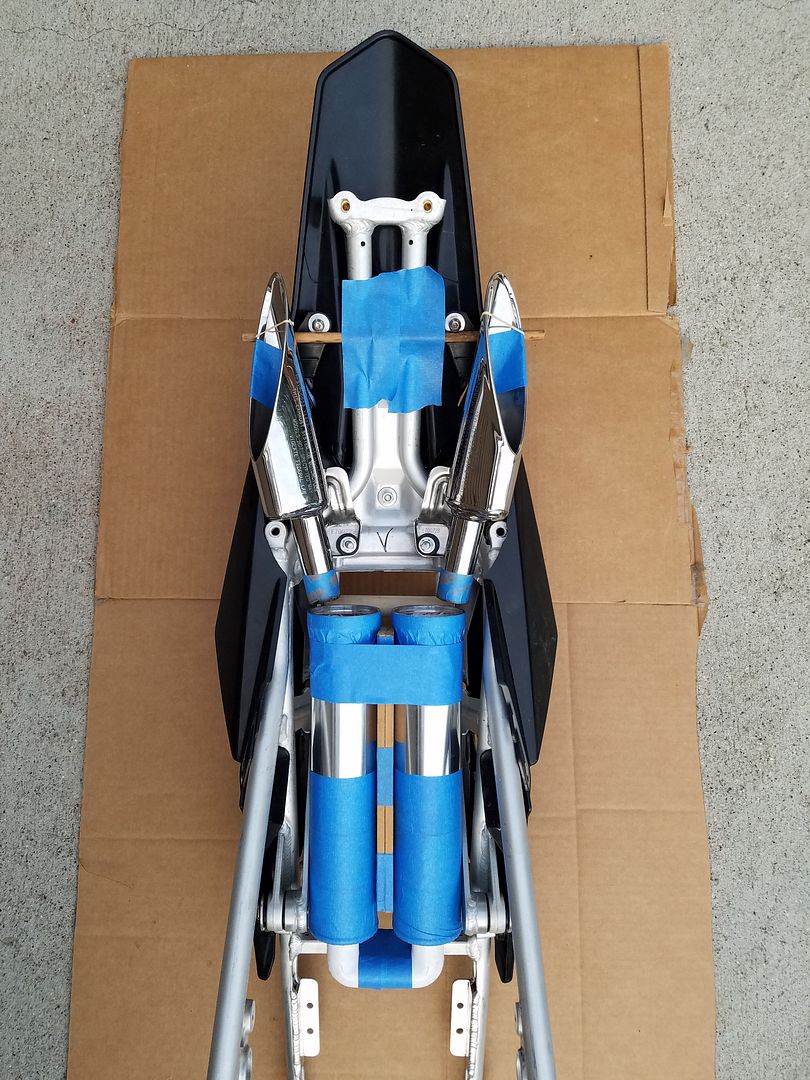

Connecting the silencers to the exhaust tips is a little more complicated.

Need to work more on a jig for holding the tips in place.

Need to chop out the rest of the tube on the exhaust tips, but the mounting bracket is welded there. Won't be easy to fit and reweld the brackets to the new tubes.

Need 1" OD stainless mandrel bent tubes shaped to go around the bolt on the mounting bracket.

Now considering custom tubing for the in and out tubes, to prevent extra welds and collars. Been reading about CNC Tube Bending.

Need to work more on a jig for holding the tips in place.

Need to chop out the rest of the tube on the exhaust tips, but the mounting bracket is welded there. Won't be easy to fit and reweld the brackets to the new tubes.

Need 1" OD stainless mandrel bent tubes shaped to go around the bolt on the mounting bracket.

Now considering custom tubing for the in and out tubes, to prevent extra welds and collars. Been reading about CNC Tube Bending.

- two-stroke-brit

- -----

- Posts: 1701

- Joined: Fri Nov 22, 2013 10:49 pm

- Location: Houston texas

Re: RZ350 Super Motard

there are some fantastic you tube vids of CNC bending machines in action

350LC,Athena 392 big bore,stock porting,swiss cheese air box,stock reeds,spec11 pipes.(now TSA big bore pipes)

She might not be pretty but she will always be a fun ride

1982 YAMA RD350LC

98KDX 220R

1967 TRIUMPH TIGER

2001 TRIUMPH TT600

She might not be pretty but she will always be a fun ride

1982 YAMA RD350LC

98KDX 220R

1967 TRIUMPH TIGER

2001 TRIUMPH TT600

Re: RZ350 Super Motard

You could think about putting 1" to 1 1/2" "caps" on the back of the silencers and letting the tips meet the caps at whatever point and angle they naturaly do before the brackets. Allowing the exhaust sound wave to hit the end of the cap and have to redirect to exit the tip isn't effecting performance at that point but will lower the noise level a bit. On my GSxRD400 after building the pipes with Toomey silencers it was a bit loud for me so I experimented with adding a 3" section the same id as the silencer right before the silencer, nothing in it just a place for the sound waves to expand and cancel each other out a bit, worked great, reduced sound level by 3db and eliminated ALOT of the "machine gun' sound as you roll off the throttle. It was an idea Tom Turner had told me that he'd used before. It didn't effect performance at all. Yours would be after your silencers but the same type of effect and something factory silencers do using space and redirection to help the sound waves cancel themselves out a bit before exiting the silencer might not be a bad idea.

http://www.erlenbachracing.co" onclick="window.open(this.href);return false;

Re: RZ350 Super Motard

Thanks for the info, Ed. Will have to see if I can get some custom tubes that will fit right. Not any wiggle room - the silencers and tips need to stay right where they are.EE wrote:You could think about putting 1" to 1 1/2" "caps" on the back of the silencers and letting the tips meet the caps at whatever point and angle they naturaly do before the brackets.

If I have to connect the silencers to the tips at a funny angle, good to know it won't be so bad for performance.

Next, need to chop the seat rail to raise the front of the silencers as much as possible. Trying to get them flush with the bottom of the battery box.

Ordering some 1 5/8" OD aluminum tubing which I can section to fill the cuts in the seat rail.

Re: RZ350 Super Motard

Got the titanium and aluminum hardware for the carb tops and bowls. Not much else to do.

Maybe custom titanium slide adjusters and nuts.

Maybe custom titanium slide adjusters and nuts.

Last edited by Smoker on Sun Oct 01, 2017 11:35 pm, edited 1 time in total.

Re: RZ350 Super Motard

Cut and filed the seat rail by hand.

Having difficulty making a jig to scribe an accurate line on the outside of the aluminum tube.

Having difficulty making a jig to scribe an accurate line on the outside of the aluminum tube.

Last edited by Smoker on Sun Oct 01, 2017 11:35 pm, edited 1 time in total.

Re: RZ350 Super Motard

Can't you just set it into the grooves you cut and draw a line along the cross member, or am I misunderstanding?

Is there much load on that cross member, there isn't much of it left.

Is there much load on that cross member, there isn't much of it left.

Re: RZ350 Super Motard

The aluminum tube had nice square cuts on the ends. I wanted to mark the tube all the way around, then cut a slice off the end. That way, I had 2 square cuts to use. I measured the seat rail with a micrometer and cut the tube to 14.30mm. Put the tube inside a new aluminum channel and clamped a stop inside. I used the end of the channel to steady the scribe while rotating the tube.RuZty wrote:Can't you just set it into the grooves you cut and draw a line along the cross member, or am I misunderstanding?

Is there much load on that cross member, there isn't much of it left.

Cut a tube slice with a hacksaw, then carefully filed it to size. Chopped it into 2 pieces with a Dremel. Just need to trim down and file the ends.

The seat rail should be strong enough after the tubing is welded in. The rail is less than 6" long and strongly welded on the ends. There's a new 3" wide crossbrace next to it (my new battery box), but if necessary, I could add gussets from the seat rail to the subframe. The seat attaches to the tank in the front and the subframe in the rear, so I don't see any safety issues.

Re: RZ350 Super Motard

Nicely done. I keep meaning to ask, are you doing all this aluminum welding? If you are you've got really good at it.

Re: RZ350 Super Motard

I wish the welding was my work.RuZty wrote:Nicely done. I keep meaning to ask, are you doing all this aluminum welding? If you are you've got really good at it.

I'm tacking the parts myself and taking them to Roger Green. His welding shop isn't far from me.

I would love to practice and get that good, but I'm running out of time. The more things I do myself, the longer these bikes take - and there's still plenty of work I need to do.

I'm just hoping I can go back to regular riding (after this crash).

Re: RZ350 Super Motard

Need to clean up the welds with a file.

Would like to go ahead with the silencer mounting brackets, but it's probably smarter to make the stainless exhaust flanges first.