Page 6 of 8

Re: Need Help With Tank Calculation

Posted: Thu Aug 23, 2018 11:34 am

by Smoker

Looks like the smallest detail is the neck on the "Man".

Anybody have an idea how small that cut could be, or how large it needs to be? Just wondering how small the machine tools are.

The plate is 6Al4V titanium, probably 5mm thick. Depth of cuts would be 3mm. Once I know the machining is possible (mill, CNC, laser, EDM, whatever), I'll order the titanium.

I don't mind paying to get the CAD drawing done. Should be able to find someone that does it for a living.

Re: Need Help With Tank Calculation

Posted: Fri Aug 24, 2018 2:20 pm

by Jeff B

Here's what I'd use to rough it.

https://www.kyocera-sgstool.com/uploads ... ARB_AP.pdf" onclick="window.open(this.href);return false;

Re: Need Help With Tank Calculation

Posted: Sun Aug 26, 2018 3:08 pm

by MK

How about asking at a jewlery or maybe electronics company for PCB's about etching the plate?

Re: Need Help With Tank Calculation

Posted: Sat Sep 01, 2018 10:40 am

by Smoker

Sent an email to the laser cutting company.

They apologized and said they forgot about my project.

Fuck me. Never get a break.

Finally spoke to the laser machinist. More bad news. He said the machine uses 15 inches of the tube to hold it. Great. I sent 2 titanium tubes, 36 inches each. Looks like half the tubing will be unusable, and I'll need to buy more.

Waiting to see exactly how many pieces he can cut from the 2 tubes.

Re: Need Help With Tank Calculation

Posted: Sat Sep 01, 2018 3:04 pm

by MK

What if they just machine a 15 inch long Al bar to match the inner diameter of the Ti tube and use a hose clamp to fix it on the bar?

Laser cutting does not need a tight fixture.

Re: Need Help With Tank Calculation

Posted: Sat Sep 01, 2018 7:20 pm

by Jeff B

MK wrote:What if they just machine a 15 inch long Al bar to match the inner diameter of the Ti tube and use a hose clamp to fix it on the bar?

Laser cutting does not need a tight fixture.

I agree that there must be a way to waste less than 15"! I suppose they normally cut cheap material that comes in long lengths where being wasteful is more cost effective.

Heck, you could weld the two 15" pieces together. Then your down to little more than 15" of waste.

Re: Need Help With Tank Calculation

Posted: Sun Sep 02, 2018 1:12 am

by Smoker

There's definitely a way to reduce the amount of wasted titanium.

Just don't think the laser cutting company could give a shit about my less than $300 usd order.

Even more work on their part, to save a few hundred for the customer? I don't think so.

I'll suggest you're ideas, and thanks for trying to help me save some cash.

Should hear something soon.

Re: Need Help With Tank Calculation

Posted: Sun Sep 02, 2018 8:25 am

by Smoker

Would have been nice if they mentioned the 15 inch clamping requirement before now!

Re: Need Help With Tank Calculation

Posted: Wed Sep 05, 2018 12:14 pm

by Smoker

I was told, the laser company would give me a call when they figured out how many pieces they could get from my titanium tubing.

Just got the call. Pieces are done. Somehow, they got all 16 pieces I asked for.

Hope my calculations are okay, and their cutting is accurate.

Going in person to pick up the parts today. Will ask about cutting the titanium plaques.

Re: Need Help With Tank Calculation

Posted: Wed Sep 05, 2018 3:07 pm

by silverstrom

Progress...at last! I'm hoping your luck has changed and this can be done quickly.

Re: Need Help With Tank Calculation

Posted: Thu Sep 06, 2018 8:23 am

by Smoker

silverstrom wrote:Progress...at last! I'm hoping your luck has changed and this can be done quickly.

I appreciate the sentiment, but no....

Paid $280 for the titanium and $225 for the laser cutting.

Short side of each piece should be close to 35.19mm. All pieces too long. Most are 36.48 - 36.72mm.

Long side should be close to 75.92mm. All pieces too short. Range from 74.98 - 75.79mm

Cut angle should be 15 degrees. All but one are 14.5 degrees. One side of one piece is 15.5 degrees.

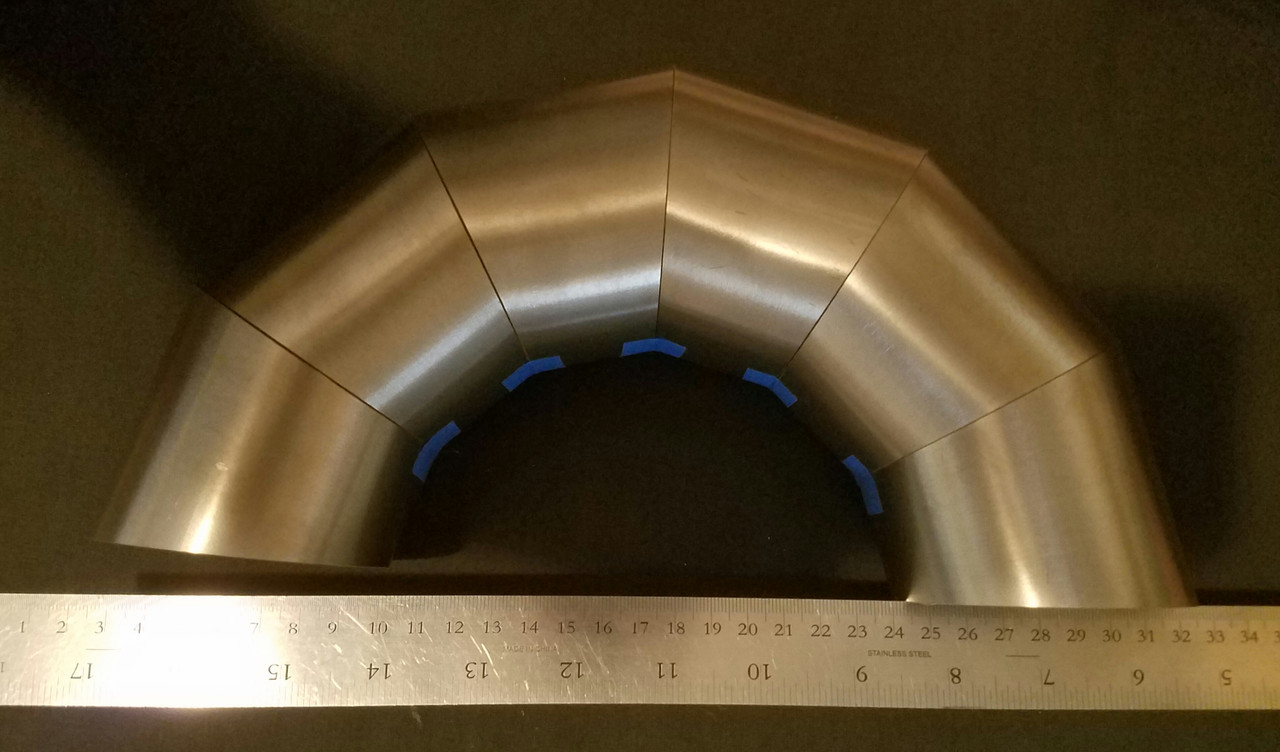

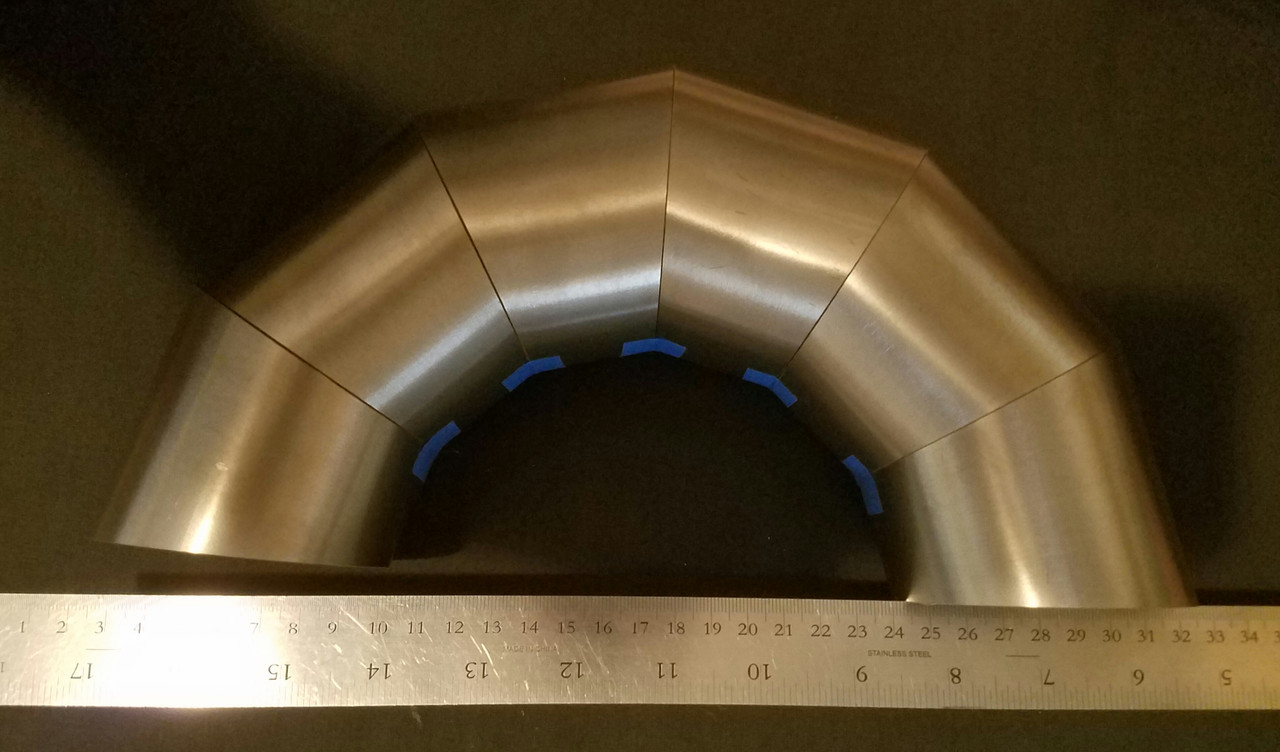

Knew it was bad right away. 6 pieces should make a half circle.

Re: Need Help With Tank Calculation

Posted: Thu Sep 06, 2018 12:40 pm

by MK

F...k.

That was an expensive experience!

How about sending the pieces "as is"?

I'd give it a try on a flat grinder which is done all the time to match single pipe segments.

You can also slightly rotate the pieces to get a slightly different angle.

Re: Need Help With Tank Calculation

Posted: Fri Sep 07, 2018 12:35 pm

by Smoker

Thanks for your support, Martin!

Things are getting more difficult as time passes. Trying my best to continue on with the projects and stay positive. Still unsure if this, or other projects, can be completed. All my projects are built on the fly, without much planning, and things change a lot as I go. It's fun, but makes it harder to finish.

I sent the laser company measurements from the pieces they cut, and didn't ask for anything. Got an email back saying their standard tolerance for cutting is 0.01 inch. They weren't anywhere close to that with my stuff. Evidently, the problem was having to common line cut the pieces [because of limited tubing]. "We need to space them out and lead in to the cuts". They offered me a refund or recut.

So, I could use these parts and get my money back.

Not my style, though. I'll buy more titanium and hope they get it right. Will need to buy more titanium than last time. Waiting for the laser company to tell me how much tubing they need.

Re: Need Help With Tank Calculation

Posted: Fri Sep 07, 2018 2:21 pm

by Jeff B

Did you tell them what the tubing cost you?

Re: Need Help With Tank Calculation

Posted: Sun Sep 09, 2018 11:06 am

by Smoker

Jeff B wrote:Did you tell them what the tubing cost you?

Yep.

I don't expect to get that money back.