You'll need to make a rod holder. A piece of steel with a 10mm hole drilled in it and then a slot cut up to meet the hole will do;

You'll also need a spring compressor. A piece of pipe with two tapped holes to accomodate a pair of screws or bolts will work. I used the tubular part of a flywheel holding tool;

Undo the cap and drain the old oil out. Then use the spring compressor with the bolts fitting into the holes in the spacer;

Push the spring down and have an assistant put the rod holder in place;

Remove the cap bolt and adjuster assembly;

Undo the nut and you can then remove the spacer, spring seat and spring. Then remove the outer tube and remove your old seals, washer and clip;

If you want to remove the damper rod assembly, use an impact wrench to loosen the cap head bolt at the base of the fork leg. Then put a long reach screwdriver down the inside of the tube and another through the hole in the inner tube to hold the damper rod in place while undoing the cap head screw all the way out.

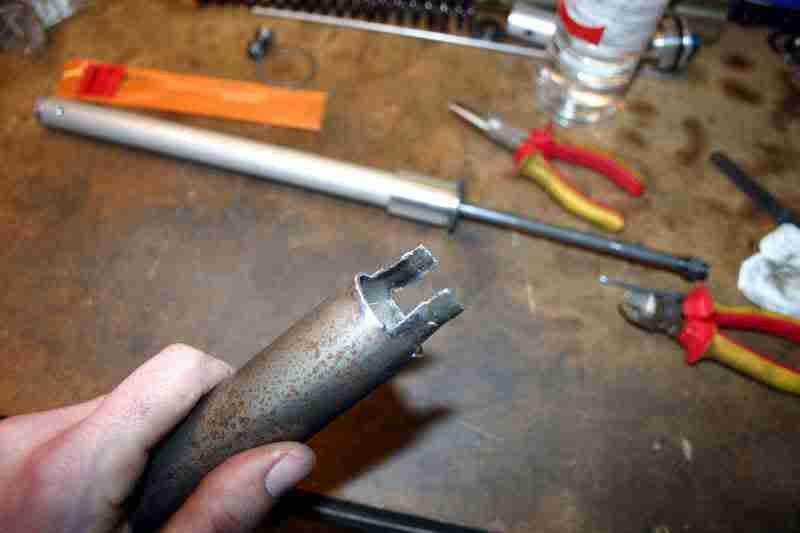

You will then end up with this;

Once you have the damper rod asembly out, you can make a holding tool to fit. I used a piece of pipe and removed material at one end to form two tangs. This is required to put it all back togethter;

Remove all the paint off the bottom of the fork leg;

Use a flap wheel to abrade the casting seams off the alloy casting;

Abrade the alloy to a satin finish and then polish to a mirror finish;

Use your damper rod holding tool to put your damper rod back in. Make sure to use a new copper washer on the cap head bolt and put thread locking compound on the threads. Torque it to 40Nm

Assemble your washer, new seals and clip;

Make a seal driving tool. A straight connector for 40mm PVC pipe with one side slit open works fine. Available from BandQ, Homebase, Lowes, Home Depot etc!

Put the dust seal and oil seal onto the inner tube. Grease them up with lithium grease first. Put a plastic bag over the top of the inner tube and lube it up before you push the seals on, to prevent the sharp edge of the inner tube cutting the rubber seals. Then put your seal driver over the inner tube as shown and push the outer tube on;

Now put a jubilee/hoseclip around your seal driver and tighten it up really tight;

Whack the oil seal in and remove the seal driver. Put your new clip in and make sure it is fully seated in its groove. Then push the dust seal into place.This can usually be done by hand, without using the seal driver.

Now put your partially assembled fork leg into your Mexican fork leg holder;

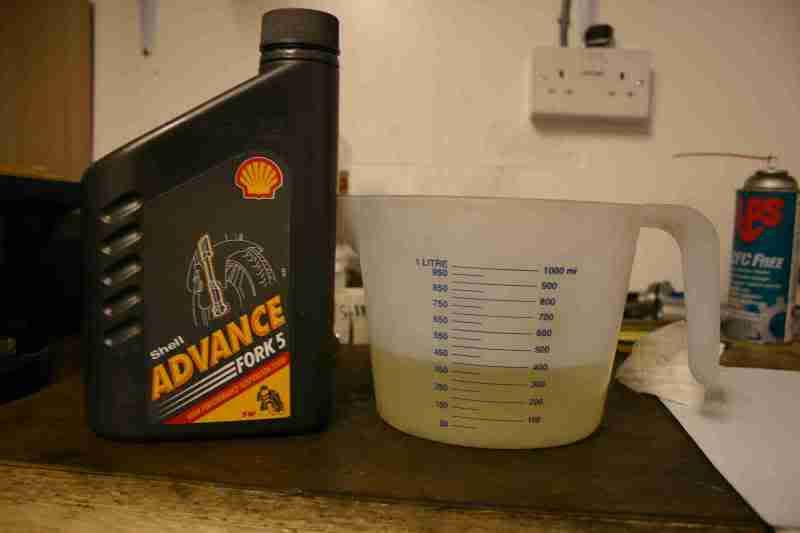

Measure out about 450ml of fork oil. I'm using grade 5;

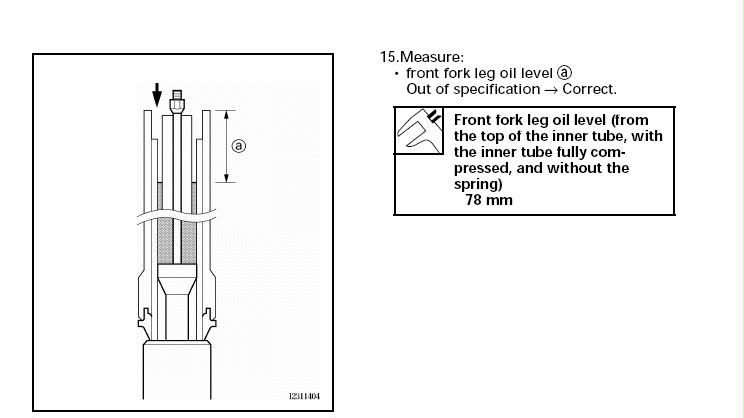

Pour the oil in, then pump the damper rod up and down about 10 times to get all the air out. Then pump the outer tube up and down several times. Do all this pumping slowly and then leave to stand for 10 mins to allow the oil to settle and all the air to escape. The capacity is 477ml, so now you will need to add more oil. Add oil slowly to bring the level up to a position 78mm below the top of the inner tube. Incidentally, one of those "pick up" magnets is ideal for lifting the damper rod up and down;

Adjust the nut on the damper rod such that it is 11mm below the top of the rod.

Feed the spring, the spring seat and the spacer down over the top of your magnetic "pick up " tool and down into the fork leg. Again using your spring compressor, push on the spacer while an assistant pulls the damper rod up with the magnet and then slips the holder into place;

Screw on your top cap and then tighten it against the nut (15Nm) but dont forget to put your damper adjusting rod down through the hole in the damper rod first. Push down on the spacer again while your assistant quickly removes the holder, then remove the spring compressor.

Pull up the outer tube and hand tighten the cap for now.You can tighten it fully when the forks are clamped in the yokes. Repeat the procedure on the other leg. Et Voila, two reconditioned, polished R1 forks, ready to go into my RD500. I must call Nigel and see if my modified yokes are ready yet.